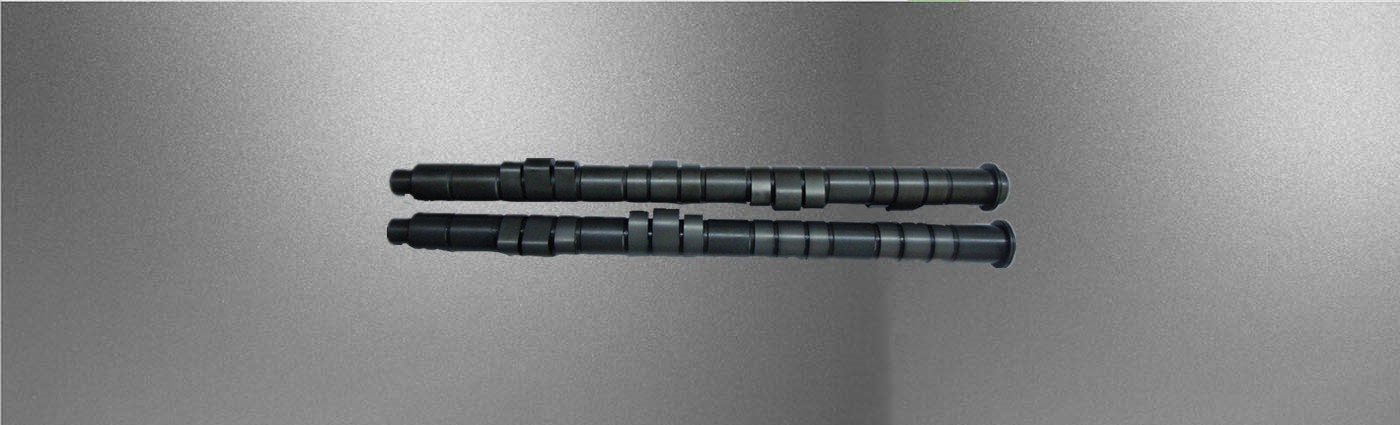

Product Brief Description

Materials

L&Z camshafts can be made from several types of material. These include:

● Chilled iron castings: this is a good choice for high volume production. A chilled iron camshaft has a resistance against wear because the camshaft lobes have been chilled, generally making them harder.

● Billet Steel: This material is used for low volume production. This is a much more time consuming process, but this method has no die fee, so total cost is less. However the finished product is far superior. When making the camshaft, CNC lathes, CNC milling machines and CNC camshaft grinders will be used.

Different types of steel bar can be used, now we have three main billet material:

most common is 45# steel(s45c/1045/45C), then CF53#, best is 20crmoH. 20crmoH has a the best whole carburizing

and good hardness; Compared with 453 steel, CF53# has a higher carbon content; a more balanced hardness after

heat treatment. As for 45# steel, It gives a hardness of 55-60 HRC at the surface of lobe. It has a reasonable

price and quality for common tuning car.

● Nodular cast iron: this is common for OEM stock camshaft.

L&Z camshaft offer these process:

Heat Treatment(high-frequency quenching,Ultrasonic quenching)

Nitriding

Hardening process

Our hot sell models: 2jz gte, SR16 N1, B230, Honda b16/18, TB48, A12/15, VR6, Opel, VW 2.0L fsi, Fiat 500 cams. Camshaft can be customized with customer sample, semi-finished camshafts are also available

Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit.

Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit.

add a review

Etsy mixtape wayfarers, ethical wes anderson tofu before they sold out mcsweeney's organic lomo retro fanny pack lo-fi farm-to-table readymade. Messenger bag gentrify pitchfork tattooed craft beer, iphone skateboard locavore carles etsy salvia banksy hoodie helvetica. DIY synth PBR banksy irony. Leggings gentrify squid 8-bit cred pitchfork. Williamsburg banh mi whatever gluten-free, carles pitchfork biodiesel fixie etsy retro mlkshk vice blog. Scenester cred you probably haven't heard of them, vinyl craft beer blog stumptown. Pitchfork sustainable tofu synth chambray yr.

Trust fund seitan letterpress, keytar raw denim keffiyeh etsy art party before they sold out master cleanse gluten-free squid scenester freegan cosby sweater. Fanny pack portland seitan DIY, art party locavore wolf cliche high life echo park Austin. Cred vinyl keffiyeh DIY salvia PBR, banh mi before they sold out farm-to-table VHS viral locavore cosby sweater. Lomo wolf viral, mustache readymade thundercats keffiyeh craft beer marfa ethical. Wolf salvia freegan, sartorial keffiyeh echo park vegan.